The solvent degreasing machine using acustom maple leafs jersey air max goaterra 2.0 cheap baseball jerseys cheap nba jerseys custom youth hockey jerseys luvme human hair wigs aguilas cibaeñas jersey castelli tutto nano jersey adidas yeezy prezzo basso banchero orlando jersey air max goaterra 2.0 adidas yeezy boost 350 v2 dazzling blue real hair wigs yeezy boost 350 v2 uberlube luxury lubricant solvent allows obtaining an optimal result in the cleaning of small objects, especially those with complex shapes. This is a very effective process for ensuring the sharpness of the smallest corners of a surface.

Given the importance of the investment, it is essential to contact a specialist in the field for the acquisition of your device.

Table of Contents

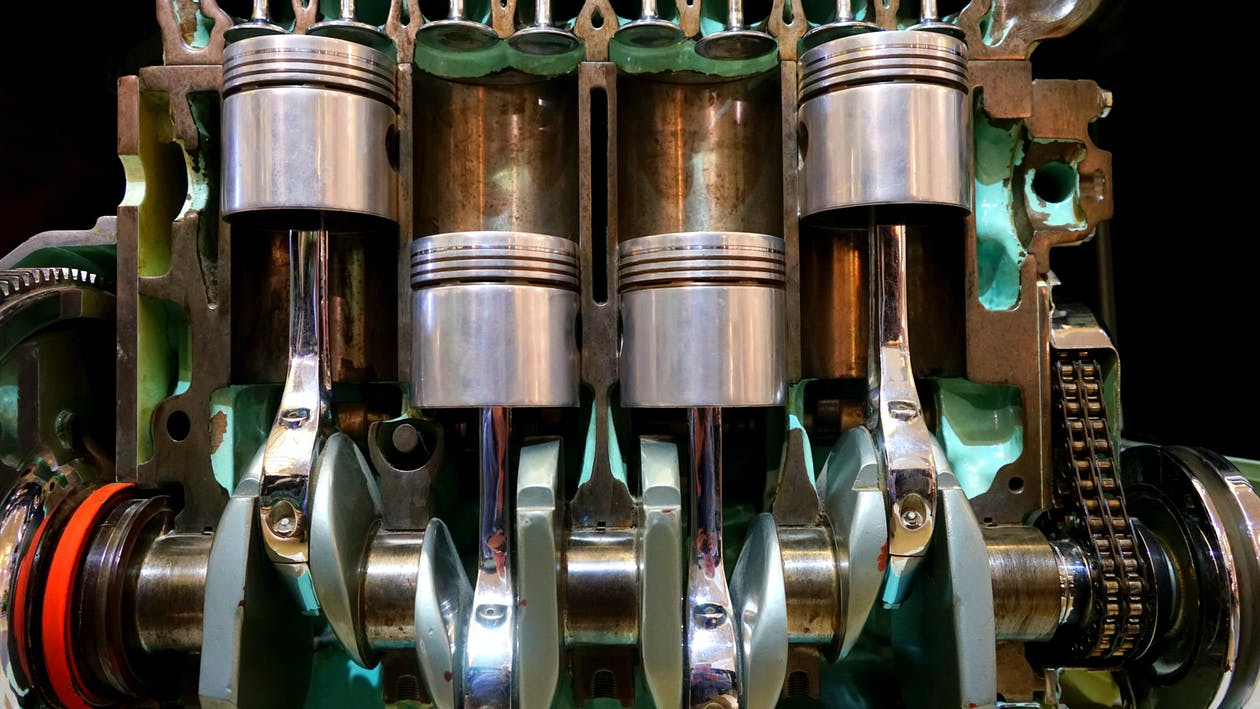

Metal degreasing process for very precise cleaning:

Solvent cleaning machines are carried out with a specific industrial machine. The process consists in taking off all the particles having adhered to the surface and even in the smallest interstices thanks to the phenomenon of cavitation. The principle is as follows: the high sound frequencies (from 20kHz to 170kHz) lead to the formation of micro-bubbles in the liquid in the tank, then these bubbles implode and the liquid infiltrates all the corners of the object to be cleaned.

Adding solvent provides better results because the action of water is limited. In addition, some solutions promote cavitation, thus producing a greater number of bubbles for better precision during washing/degreasing process of metals. In addition, it is better to operate at a temperature of around 50°C for optimum solvent efficiency.

A metal degreasing solvents process therefore essentially comprises a tank, transducers, and a high-frequency generator. The use of a specific solution is recommended, moreover, each field of application for this type of cleaning corresponds to specific solvents.

The benefits of solvent degreasing:

This process concerns many sectors: odontology, optics, laboratory, jewelry, archaeology, etc. The main advantage is to be able to degrease all surfaces, even the smallest, by removing the smallest particles (up to 15 microns). This efficiency makes it possible to clean the most complex shapes. In addition, the operation does not require the dismantling of the objects beforehand, even in the presence of different materials.

Although solvents are often used, chemical reagents are used in small quantities. Since the operation is carried out in a dedicated tank without manual handling of the solutions, there is no projection of hazardous substances.

The absence of human intervention during the process makes it possible to make the most of the time spent on degreasing and to save in terms of labor.

Finally, it is a very fast process that only takes a few minutes, twenty at most. Combined with the high cleaning precision, this processing speed makes the technique highly efficient. Ultrasonic degreasing machines and solvents are therefore essential in the industrial field.

Cleaning with solvent-based cleaners:

The solvent-based degreasing process is a common technique for cleaning parts or accessories used in the industrial and professional environment. The operation of washing operation is carried out in immersion and the solvent washing machine ends with a vapor phase. The drying of the parts at the end of the cleaning cycle takes place during the cleaning phase with steam.

Firbimatic – High-performance machines and impeccable service:

Firbimatic is one of the leading players in surface cleaning. The company provides new and used industrial washing machines, including degreasing equipment using solvents or not. We also offer liquid solutions adapted to the different fields of application.

We are present throughout Italy, and our teams are always available to study with you the most appropriate formulas for your activities, or even carry out trials together.

Customer satisfaction is our only watchword, we provide support during the purchase and guarantee quality after-sales service.

Other industrial cleaning machines are also available, using different techniques according to your activities and your needs: washing fountains by spraying or by immersion, detergent degreasing devices, sandblasting cabins, trim finishing, and drying equipment for the treatment of surfaces, etc.

Whether cleaning parts, machines, or industrial floors, Firbimatic can provide the most suitable solution.